产品介绍 performance introduction

SHG系列是2015年黑龙江艾尔机械制造有限公司结合木业、地板表板、家居面板、立刨等行业设计的一款表板烘干机。

该机型主要用于烘干名贵的天然家具用木皮,刨切木皮,实木复合地板的表板等。采用了非常昂贵且网孔很密的不锈钢网带干燥单板,单板表面无痕迹、污点。配置方面上采用日本三菱变频、瑞典ABB电机、英国斯派莎克疏水阀等国内外优质配件确保产品品质。结构上采用了单板输送呈S型干燥法,并使木皮在反复弯曲后消除内应力,使之烘干出来的单板平整度、光洁度达到理想效果。采用风压式气流循环系统,顶式离心风机,具有高风压,大风量之特性,散热器为钢铝复合式结构,具有散热面积大且传热效果佳的特点。采用横向循环垂直喷气方式,喷射的气流能高速均匀有效地作用于单板表面。采用了烘干室高低温区分开控制的方式,根据单板的种类、厚度、和含水状况的不同可自由选择干燥速度和加热温度。本机型采用烘干区与冷却区网带断开式,中间部分采用毛刷辊过渡,从而大幅度的减少加热区热耗以及冷却能耗。

该机型可与多种热源配套:蒸汽锅炉、导热油锅炉、及热风炉、燃气锅炉等

热源安装形式:1.下吸式 2.上吸式 备注:1.配用蒸汽锅炉,导热油炉时,热源安装形式为下吸式安装,烘干机内配有多组SRZ.SRL系列热源交换散热器.但订制烘干机时,蒸汽锅炉,导热油炉等锅炉有客户自行订制,我公司不配置锅炉。 2.配用热风炉时,公司自配用该机型专用的“ARRFL型热风炉”,同时热源安装形式为“上吸式”。 Characteristics: Expensive stainless mesh-belt with dense mesh has been adopted to dry veneers and make them tidy and clean on surface."S”type transportation in this dryer ensures required planeness and degree of finish on veneers.Air circulation system of wind pressure style and centrifugal blowers which have been mounted on top have been used.High wind pressure and large air volume can be reached.Radiator is made of steel and aluminum which has the advantage of good heat conduction and large radiating area..The air flow acts on the veneers evenly by ways of circulating horizontally and sprayed vertically.Optional drying speed and heating temperature according to the thickness and moisture content of veneers is available by the individual controls on high-temperature and low-temperature areas.Equipped with Mitsubishi branded inverter,ABB motors and SpiraxSarco steam trap,this veneer dryer enjoys high performance.Drying area and cooling area are connected by brush roller instead of mesh-belt which will save more energy on both heating and cooling

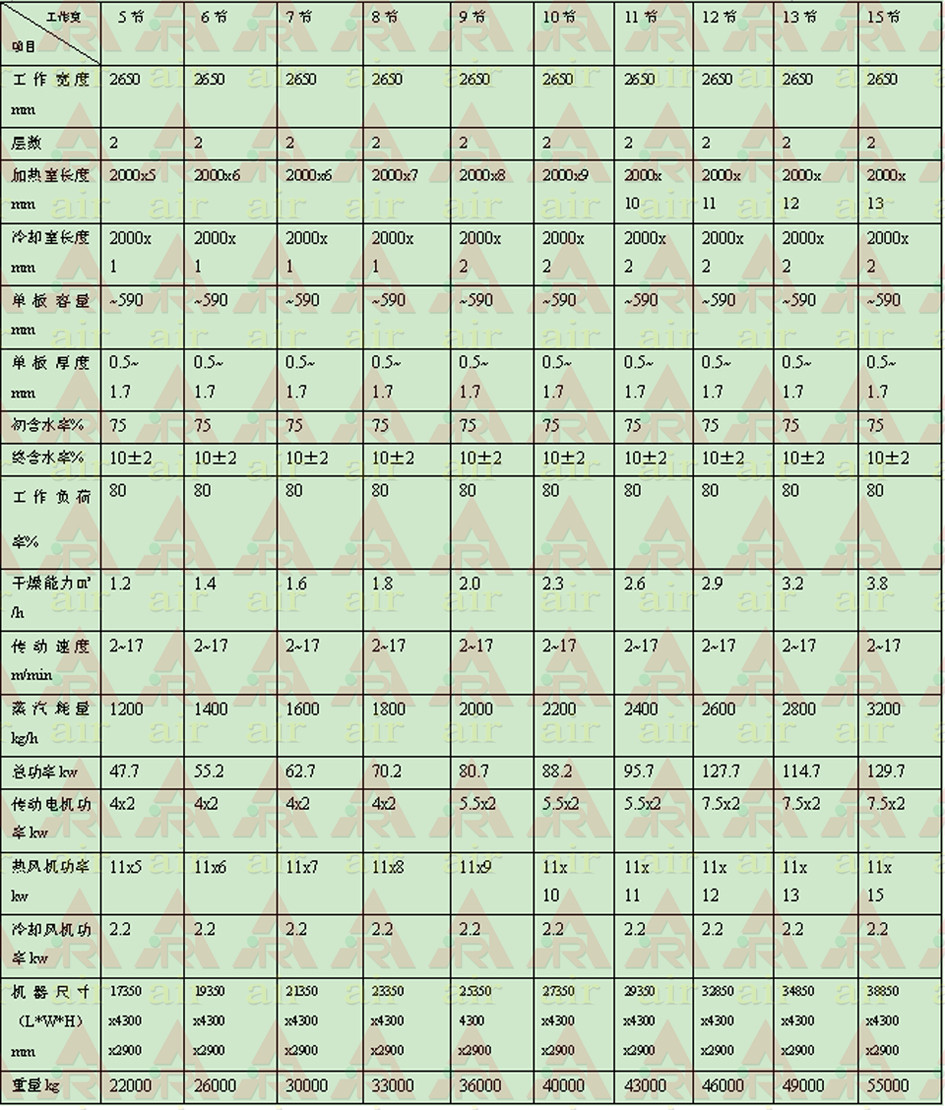

主要规格及技术参数

工作负荷率% 85 外形尺寸: 长x宽x高mm(23200~28200)x(5200~6650)x4700.

|